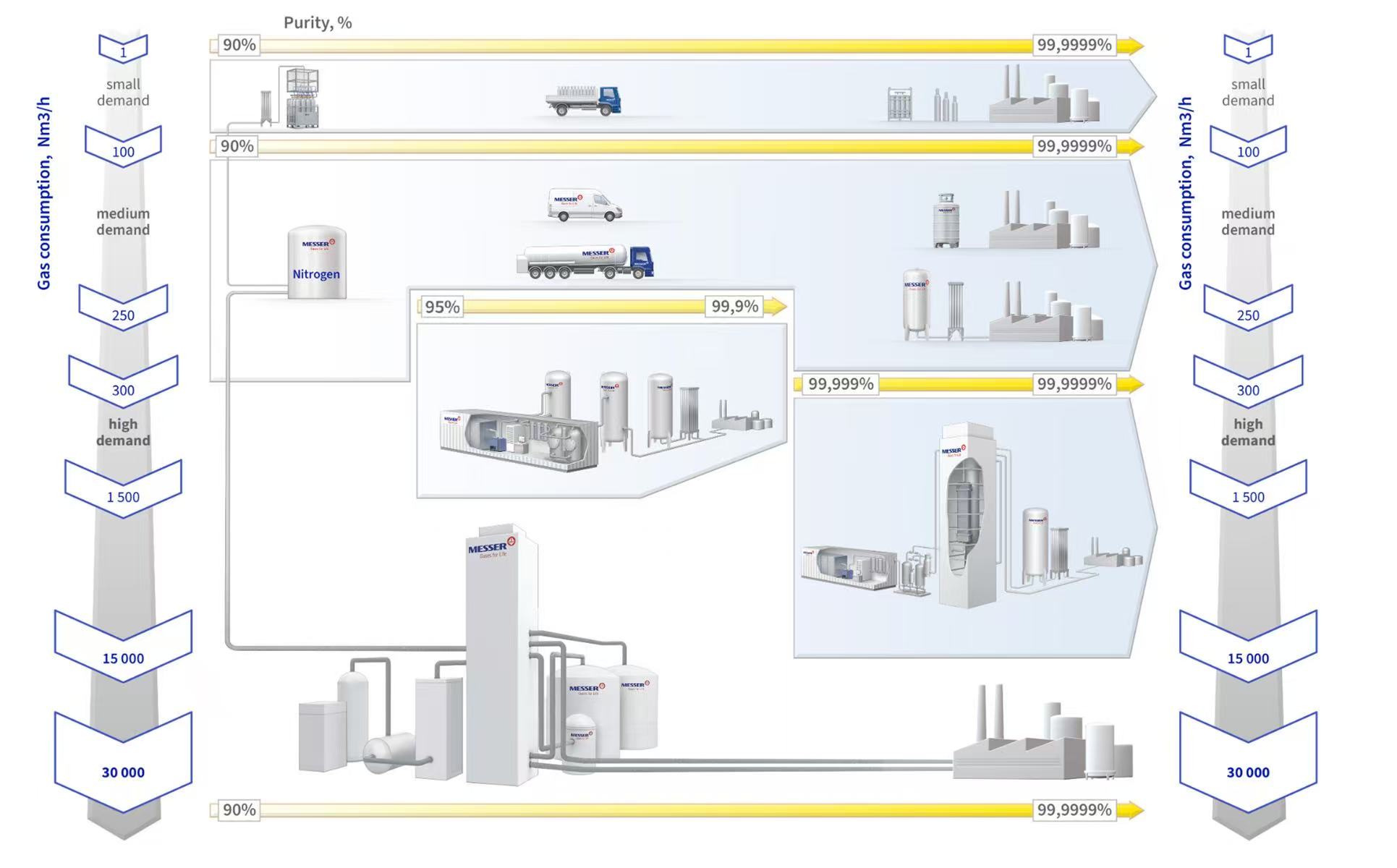

In many industries, nitrogen plays a critical role as shielding gas, purging gas, or inert atmosphere. Its stability, reliable supply, and cost efficiency are essential to ensuring continuous production. As a result, more companies are turning to on-site nitrogen generation systems to achieve greater gas independence and operational control.

Nitrogen Supply Solutions

PSA On-site Nitrogen Generation

Messer’s PSA nitrogen generation systems utilize advanced pressure swing adsorption technology. By leveraging the physical adsorption characteristics of specialized carbon molecular sieve materials, high-purity nitrogen can be produced directly without the need for cryogenic liquefaction. The system only requires a supply of clean, dry compressed air. Nitrogen purity can reach up to 99.9%. Compressed air is purified and pressurized to around 10 bar before entering the adsorption towers. While one tower produces nitrogen, the other regenerates through depressurization. The towers switch automatically, and off-gas impurities are vented to the atmosphere. The process is fully automated.

Key Specs

- • Nitrogen Capacity: 50 ~ 1,500 Nm³/h

- • Nitrogen Purity: 95% ~ 99.9(94)% (Oxygen content 5~0.1 ppm)

- • Delivery Pressure: 4~10 bar(g)

- • Load Range: 80% ~ 100%

Advantages

- • Low long-term operating costs

- • 24/7 continuous operation

- • Safe, easy to operate and convenient to maintain

- • Short construction and commissioning period

- • Significant reduction in CO₂ emissions

CryoGAN On-site Nitrogen Generation

To meet the growing demand for oxygen, as well as customer requirements around cost control and carbon emission reduction, Messer has developed the CryoGAN series of oxygen generation systems. Based on cryogenic air separation technology, CryoGAN is purpose-built for medium to large-scale gas applications, combining high efficiency with environmental benefits.

The CryoGAN system is developed in-house by Messer and features modular design, with production capacities ranging from 600 to 50,000 Nm³/h and scalable for future expansion. Backed by over 20 years of global field-proven performance, the system ensures long-term, stable and safe operation across a wide range of industries.

Key Specs

- • Nitrogen Capacity: 600 ~ 50,000 Nm³/h

- • Nitrogen Purity: 99.999%~99.9999%

- • Delivery Pressure: 0.2 ~ 10 bar(g)

- • Load Range: 40% ~ 100%

- • Availability ≥99.9%

Advantages

- • Significant reduction in CO₂ emissions

- • Customized solutions based on specific customer needs

- • 24/7 continuous operation

- • Safe and reliable, easy to operate and maintain

- • Plug-and-play installation

- • Short construction and commissioning time

Optional By-products of CryoGAN

- Compressed dry air

- Oxygen-enriched tail gas

Reliable Spare Parts System

A stable spare parts system is a critical safeguard for any on-site gas supply system. It ensures peace of mind for customers by effectively responding to unplanned inspections, maintenance, shutdowns, or other unexpected events. Leveraging Messer’s extensive regional logistics network and centralized dispatch platform, combined with our professional production planning capabilities, we can ensure timely and reliable spare parts supply to customers at any location. We always put our customers at the center. Based on specific needs, we tailor dedicated spare parts system solutions to ensure seamless backup and emergency supply for the main system, enhancing both supply continuity and operational safety.

You May Also Be Interested in

Nitrogen

Learn More >

On-site/Pipelines

Learn More >