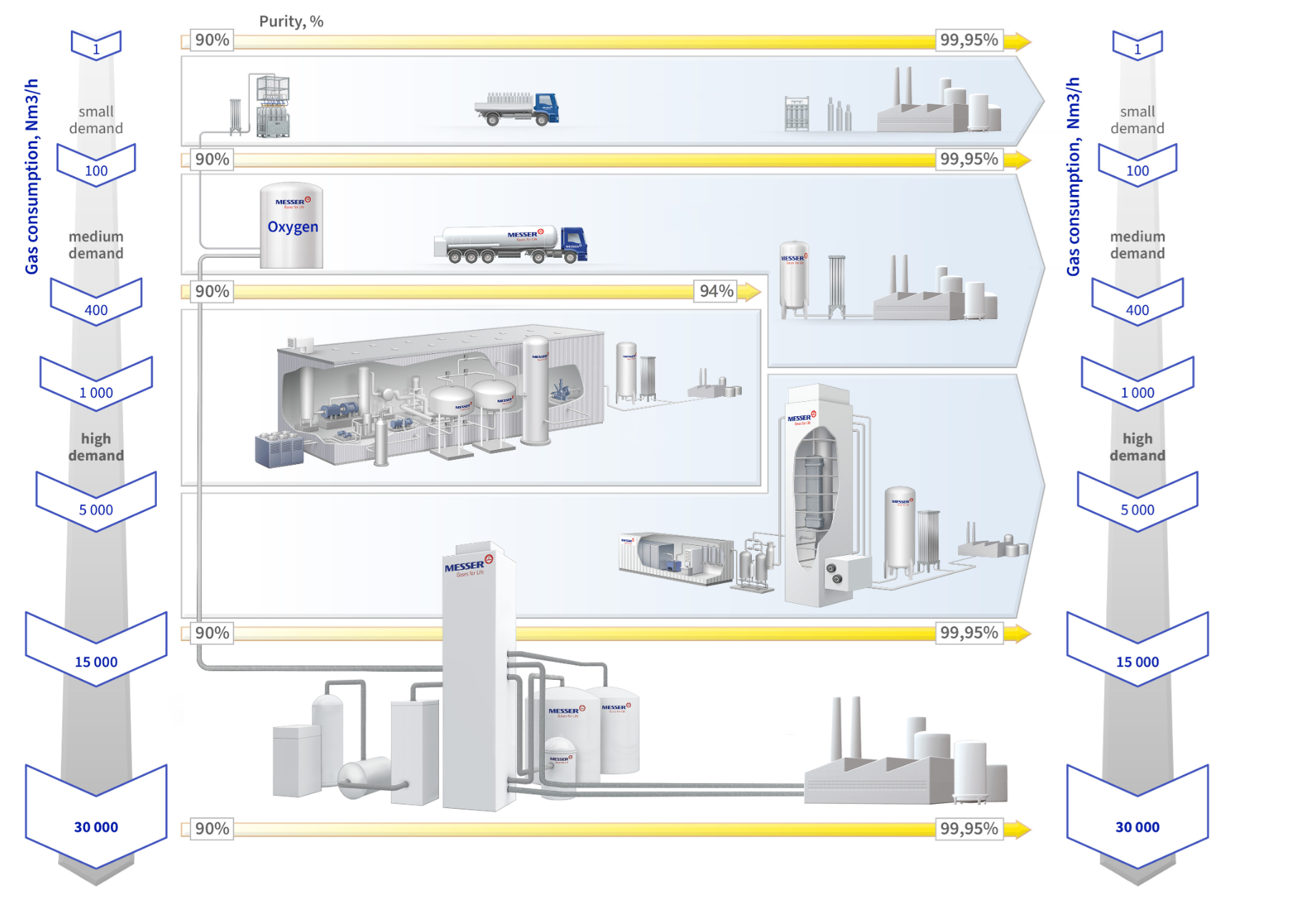

In industrial applications where long-term and stable gas demand is required, on-site generation is an efficient and cost-effective choice. These systems can be customized and configured according to specific needs to ensure continuous and reliable gas supply. Different industries often have varying requirements for gas volume and purity, and are typically linked to specific production processes. Therefore, Messer offers flexible on-site supply solutions that can be precisely designed and delivered based on the customer’s actual needs.

Not Sure Which Oxygen Supply Mode is Right?Let’s Help You Decide!

VPSA On-site Oxygen Generation

To meet the demand for high-efficiency oxygen supply in industries such as glass, metallurgy, cement, and chemicals, Messer offers VPSA oxygen generation systems that deliver outstanding reliability and industry-leading performance. The oxygen purity at the system outlet ranges from 80% to 95%, making it suitable for a wide range of industrial applications. VPSA systems operate based on the principle of selective adsorption of mixed gas components. In this process, the adsorption rate is a key factor affecting system efficiency. Oxygen is separated through the surface of the adsorbent granules without deeply penetrating into their core, enabling direct desorption by air and significantly improving overall system efficiency and energy utilization.

Key Specs

- • Oxygen Capacity: 400 ~ 5,000 Nm³/h

- • Oxygen Purity: 80% ~ 95%

- • Delivery Pressure(Booster free):0.2 bar(g)

- • Load Range: 100% ~ 40%

- • Support modular on-site installation

Advantages

- • Low long-term operating costs

- • 24/7 continuous operation

- • Safe, easy to operate, and convenient to maintain

- • Short construction and commissioning period

- • Significant reduction in CO₂ emissions

CryoGOX On-site Oxygen Generation

Key Specs

- • Oxygen Capacity: 1,000 ~ 30,000 Nm³/h

- • Oxygen Purity: 93% ~ 99.5%

- • Delivery Pressure: 0.2 ~ 10 bar(g)

- • Load Range: 50% ~ 100%

- • Availability: ≥99.9%

Avantages

- • Significant reduction in CO₂ emissions

- • Customized solutions based on specific customer needs

- • 24/7 continuous operation

- • Safe and reliable, easy to operate and maintain

- • Plug-and-play installation

- • Short construction and commissioning time

Optional By-products of CryoGAN

- Liquid Oxygen

- Compressed dry air

- Nitrogen

- Liquid Argon

Reliable Spare Parts System

A stable spare parts system is a critical safeguard for any on-site gas supply system. It ensures peace of mind for customers by effectively responding to unplanned inspections, maintenance, shutdowns, or other unexpected events. Leveraging Messer’s extensive regional logistics network and centralized dispatch platform, combined with our professional production planning capabilities, we can ensure timely and reliable spare parts supply to customers at any location. We always put our customers at the center. Based on specific needs, we tailor dedicated spare parts system solutions to ensure seamless backup and emergency supply for the main system, enhancing both supply continuity and operational safety.

You May Also Be Interested in

Oxygen

Learn More >

On-site/Pipelines

Learn More >