As a trusted expert in industrial gases, Messer has extensive experience in on-site hydrogen generation, backed by proven quality assurance, logistics, and gas supply capabilities. We have successfully delivered tailored hydrogen supply solutions to customers across a broad range of industries. In recent years, with the increasing adoption of hydrogen in high-temperature heating, glass production, and steel decarbonization, the overall demand for industrial hydrogen has continued to rise. Customers are placing greater emphasis on supply solutions that are both localized and sustainable. To meet diverse hydrogen needs across different applications, Messer delivers fully integrated on-site hydrogen solutions covering project design, equipment installation, and long-term system operation and maintenance. Our approach centers on around producing hydrogen directly at the point of use, enabling safe, efficient and cost-effective supply. By minimizing hydrogen losses during storage and transport, and reducing the emissions associated with conventional logistics, our solutions help customers enhance operational reliability while advancing their decarbonization and sustainability goals.

Three Proven Modes for On-site Hydrogen Generation

Steam Methane Reforming with Carbon Capture(SRM + CCUS)

Applications: Ideal for high-volume, continuous hydrogen users in refining, ammonia, methanol, and chemical processing industries.

Key Specs:

- Capacity: 1,000 – 50,000 Nm³/h

- Purity: 99.99 – 99.999%

- Delivery Pressure: 1.0 – 2.5 MPa

- Load Range: 50% – 100% load

- Availability: ≥ 99%

Water Electrolysis (PEM / Alkaline)

Applications: Suitable for semiconductor, photovoltaic, fuel cell hydrogen stations.

Key Specs:

- Capacity: 50 – 1,000 Nm³/h

- Purity: 99.999%

- Delivery Pressure: ≤ 1.0 MPa

- Load Range: 5% – 100% modulation

- Availability: ≥ 99%

Hydrogen Recovery from Industrial Gas Streams (PSA / Membrane Separation)

Applications: Optimal for recovery from reformer off gas, chlorine plants, PDH, and other hydrogen rich tail gas sources (H₂ > 50%).

Key Specs:

- Source: Reformer off gas or hydrogen rich byproduct streams

- Recovery Rate: 85% – 95%

- Typical Payback: ≤ 3 years

You May Also Be Interested in

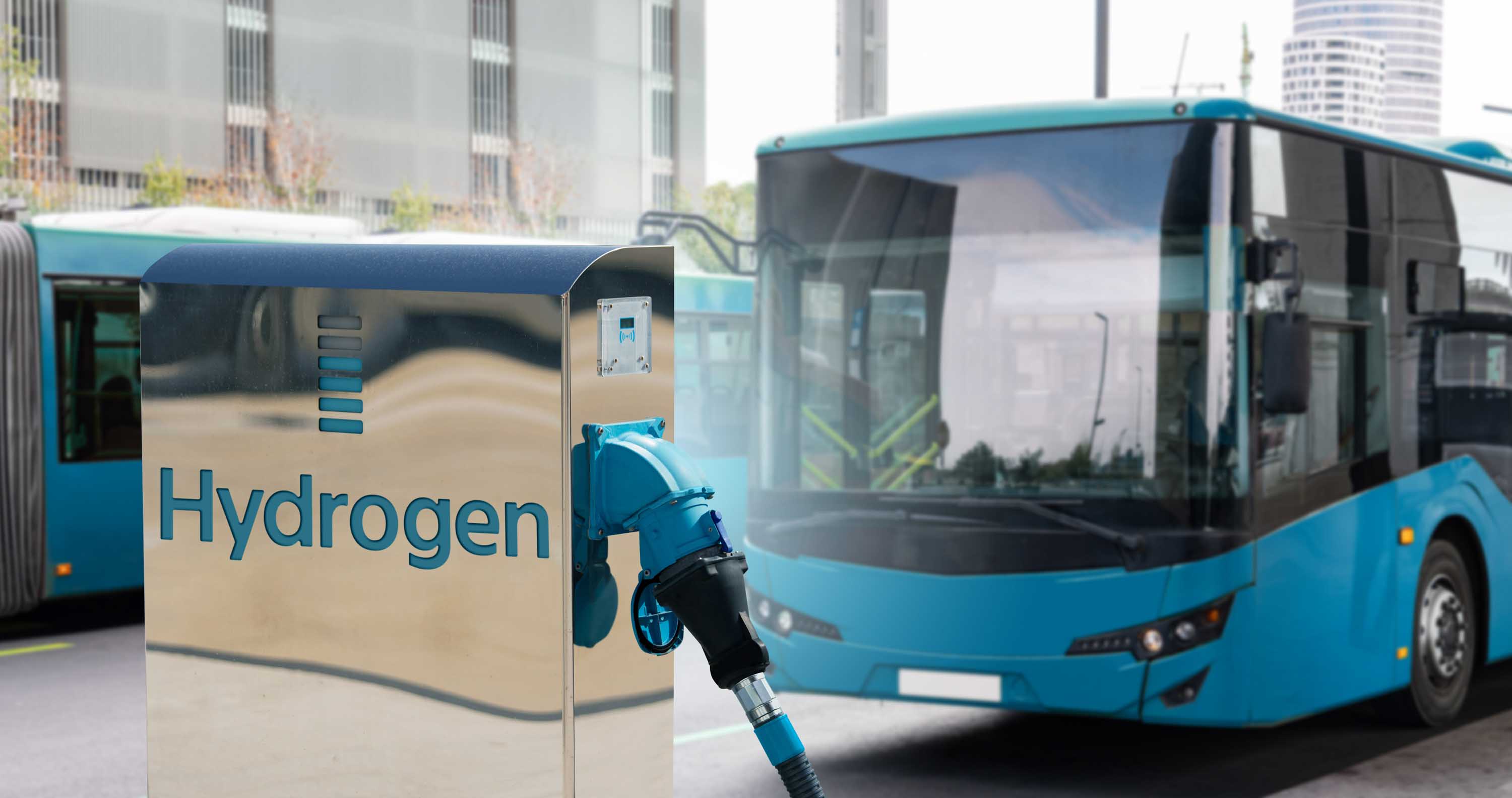

Hydrogen

Learn More >

On-site Oxygen Generation

Learn More >